Still cutting tubing manually? In today’s efficiency-driven manufacturing, saving time and labor means saving cost. As a professional tubing manufacturer, Goodgi understands material properties and production challenges. We not only recommend the most suitable automatic cutting machines, but also provide localized technical support to ensure smooth, long-term operation. Contact us today for expert assistance.

Application Scope of Cutting Machines

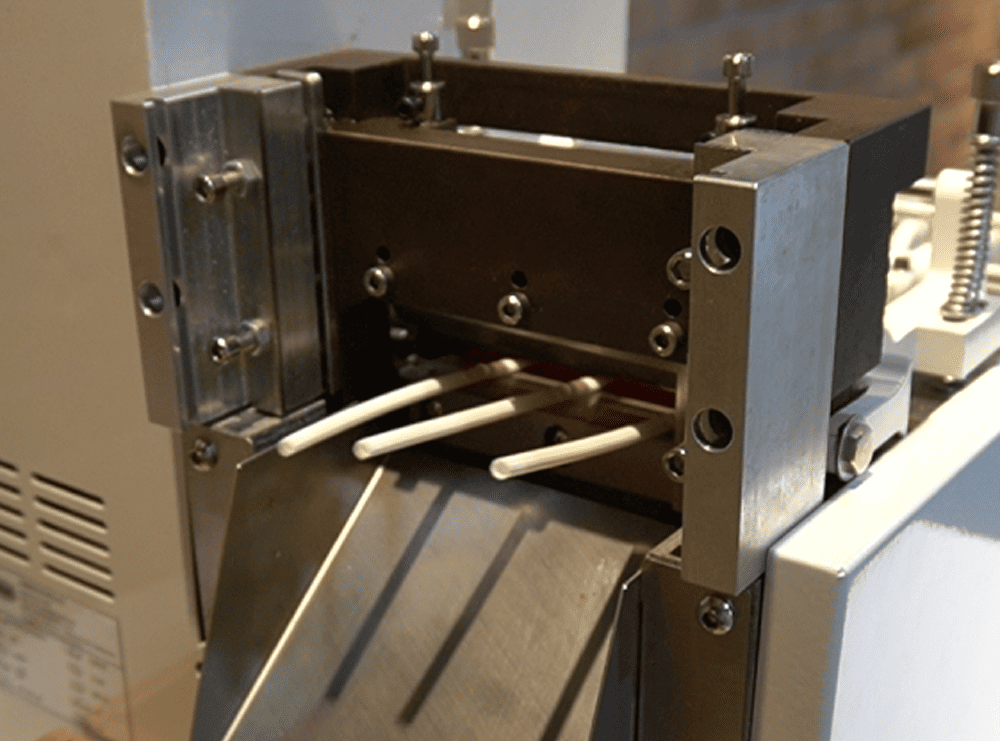

A Sleeve Cutting Machine is a type of automated cutting equipment used for handling flexible materials. It plays a vital role in manufacturing processes across industries like electronics, textiles, and automation.

Suitable Materials for Sleeve Cutting Machines

Sleeve Cutting Machines are specifically designed for soft and flexible materials, such as:

-

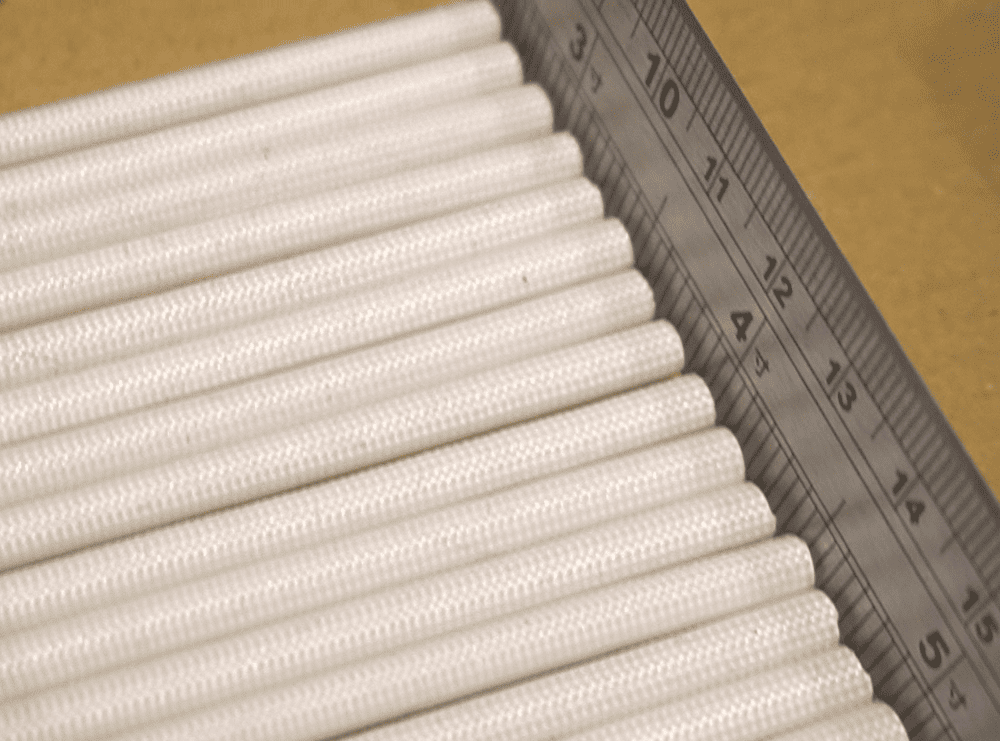

Insulation tube, Heat shrink tubing, fiberglass sleeving, PVC tubing, silicone tubing

-

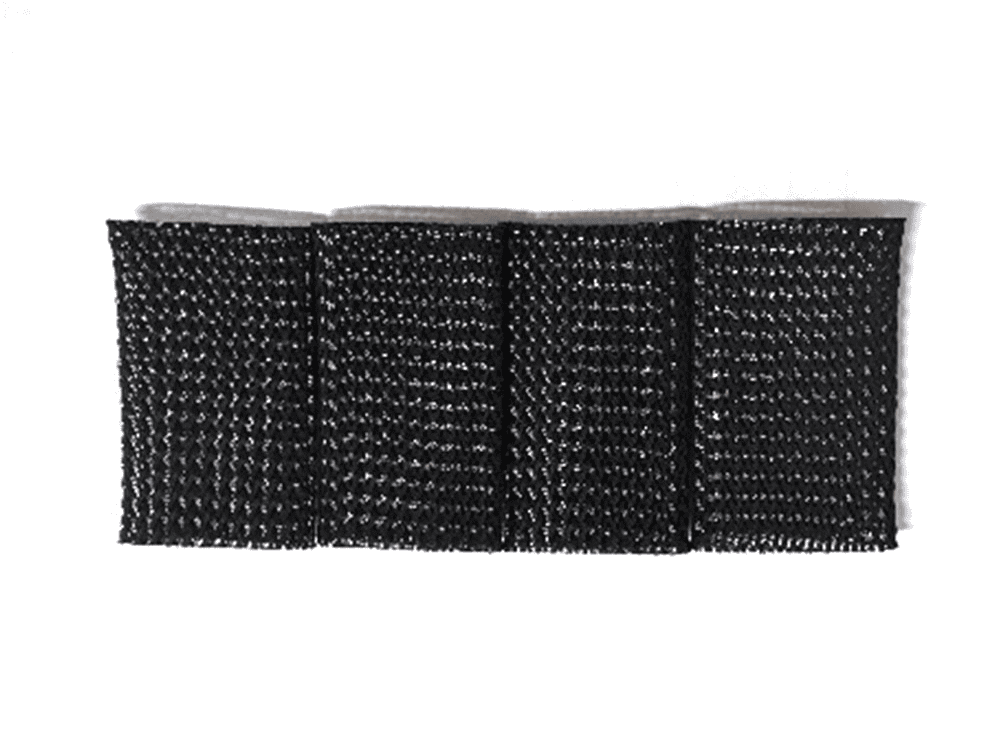

Fabric tape, woven straps

-

Velcro (hook and loop fasteners)

-

Zippers

-

Adhesive tapes, PET films

These materials can be efficiently cut using feeding belts and pressure mechanisms without distortion.

Not Suitable for Hard or Corrugated Tubing

It’s important to note that Sleeve Cutting Machines are not suitable for rigid or corrugated tubes, including:

-

Corrugated tubing /

-

Thick-wall rigid pipes

If your application involves these materials, we recommend using a Corrugated Tube Cutting Machine or a Pipe Cutter designed specifically for rigid materials, which avoids deformation during cutting.

Cutting Methods (Cold / Hot Cut)

When choosing a Sleeve Cutting Machine, you may notice that some models offer both cold cutting and hot cutting options. So, how do you decide which one is right for your application?

The difference lies in one key point: whether the blade is heated or not.

Cold Cutting — Fast, Simple, and Versatile

-

Blade Type: Non-heated (room temperature)

-

Advantages:

-

Faster cutting speed

-

Simpler mechanical design

-

Easier to maintain

-

Suitable for a wide variety of materials

-

-

Best for: Materials that do not fray or unravel, such as PVC sleeves, paper tape, PET film, or insulation tubing

Hot Cutting — Prevents Fraying and Ensures Sealed Edges

-

Blade Type: Electrically heated blade with adjustable temperature

-

Advantages:

-

Cuts and seals edges simultaneously

-

Prevents fraying of fabric and nylon-based materials

-

-

Best for: Insulation tubing (PET Expandable Braided Sleeving, Nylon Expandable Braided Sleeving, Self-wrapping Braided Sleeving), webbing, Velcro, woven cords, and other materials prone to fraying.

Which Cutting Method Should You Use?

If your material doesn't fray or require edge sealing, cold cutting is the more efficient and lower-maintenance option. However, for textiles or synthetic fabrics that tend to unravel, a hot cutting machine will give you cleaner results and better durability.

Corrugated / Rigid Tube Cutter Models

When working with corrugated tubes or rigid pipes, choosing the correct Sleeve Cutting Machine is crucial for ensuring precise results and maintaining material integrity.

Different Tube Types Require Specialized Cutting Machines

The structure and material of your tube determine the cutting mechanism:

Standard Sleeve Cutting Machine (for soft or flat tubing):These machines typically use a lower conveyor feeding system, which slightly compresses the material during cutting. This helps with alignment and stability — ideal for soft, flexible sleeves.

-

Corrugated/Rigid Tube Cutters:Designed with dual-sided (upper and lower) feeding belts that push the tube forward without compressing it. This is essential for rigid materials that need to maintain their original shape for accurate cutting.

Maintain Shape, Achieve Precision

Using the wrong cutting system — especially one that compresses the tube — can lead to deformation and inaccurate cuts. For hard plastic tubing or corrugated hoses, machines with upper and lower drive belts provide stable movement while preserving the tube’s form, resulting in high-precision cutting.

Key Features of High-Quality Cutting Machines

Choosing the right Sleeve Cutting Machine can significantly improve production efficiency and product quality. Here are two essential features to look for:

User-Friendly Interface & Smart Automation — Reducing Labor and Boosting Efficiency

Modern sleeve cutting machines are equipped with intuitive, operator-friendly interfaces and smart automation features. Once the desired cut lengths and quantities are programmed, the machine runs automatically without the need for constant monitoring. This results in a faster, more consistent, and precise production process—minimizing the risk of human error and lowering labor requirements.

High Cutting Precision — Maintain Strict Tolerances

Precision is the core of any sleeve cutting process. A quality machine must ensure accurate cuts in terms of thickness, width, and length — all within tight tolerance levels. This reduces material waste, minimizes defects, and guarantees consistent product quality across all batches.

Factors Affecting Cutting Tolerance

Choosing the right cutting machine is all about controlling dimensional tolerance. The accuracy and consistency of each cut directly impact downstream processing and assembly quality.

Common factors include:

-

Material properties – Differences in thickness, hardness, and elasticity affect cutting resistance. Greater resistance may increase vibration, resulting in size deviation.

-

Machine setup and process – The cutting method, speed, feed precision, and belt tension are all interconnected factors that influence tolerance variation.

Tolerance Optimization Methods

Tolerance variations stem from material type, cutting speed, and feed precision. Solutions include: selecting the proper machine type, optimizing cutting parameters, and performing regular calibration and maintenance.

Why Choose Goodgi

Competitive Pricing — Optimize Your Budget

Based on local market research, GoodGi offers more competitive pricing plans to help you reduce costs without compromising on quality.Get a Quote Now

In-House Technical Team — Custom Support & Consultation

Our experienced in-house engineers provide customized solutions and one-on-one consultation services tailored to your project needs, ensuring efficient and timely support.

Long-Term Partnership — One-Stop Equipment & Material Supply

GoodGi is more than just a cutting machine provider — we are also a professional manufacturer of insulation tubing. When you use both our machines and materials, it enables closer, long-term collaboration. This allows us to monitor your equipment performance and offer real-time support and maintenance more efficiently.