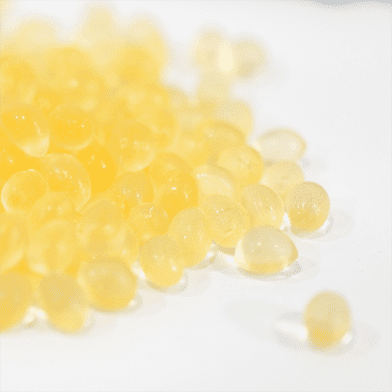

Low pressure molding Hot Melt Adhesive

Introduction

The low-pressure injection process, also known as low-pressure injection molding, is a packaging process in which low-pressure injection materials are injected into the mold at a very low injection pressure (1.5 to 40 bar) and rapidly cured (several seconds to minutes).

The excellent sealing and excellent physical and chemical properties of low-pressure injection polyamide can achieve the functions of insulation, temperature resistance, impact resistance, shock absorption, moisture resistance, waterproof, dustproof, chemical corrosion resistance, etc., and play a good role in protecting electronic components effect.

Compared with traditional potting processes (such as two-component epoxy or silicone potting), low-pressure injection is not only environmentally friendly but also greatly improved production efficiency and can help reduce overall costs.

Compared with low-pressure injection, the high-pressure injection has large injection pressure and high injection temperature, and fragile precision components are easily damaged during the injection process, which easily leads to a high defect rate in the production process.

In view of the defects of high-pressure injection, Good Gi Co., Ltd selected low-pressure injection hot-melt adhesive series products with low viscosity and high fluidity for customers. In a small mold space, the fragile components that need to be packaged will not be damaged, which greatly reduces the scrap rate.

In addition, in terms of molds, low-pressure forming molds can be cast as aluminum molds instead of steel, so it is very easy to design, develop and manufacture molds, which can shorten the development time. In addition, compared with the time-consuming traditional high-pressure injection molding, the processing time of low-pressure injection molding can be shortened from a few seconds to tens of seconds, which greatly improves the production efficiency.

It can be used in wiring harnesses and connectors, transformers, computer peripheral wires, micro switches, sensors, power supplies, mobile phone batteries, fiber optic components, plug packaging and PCB/ECU packaging, automotive electrical parts, electronic parts and etc.

All of the above characteristics tell us that low-pressure injection molding technology can make up for the shortcomings of traditional high-pressure injection molding, and become the best solution for small electronic and electrical components, providing mechanochemical protection with long-term reliability to reduce costs, and improving benefits.

Good Gi Co., Ltd provides professional low-pressure injection molding solutions, providing low-pressure injection materials, low-pressure injection machines, low-pressure injection molds, low-pressure injection OEMs, one-stop service, and customized mold development according to the different injection parts of customers.

| Product Name | Hardness | Operating Temp. | Viscosity(mPa·s) | |

|---|---|---|---|---|

|

Hot Melt Adhesive

8807/8807A

|

90A | -40℃~105℃ | 4000(mPa·s)/210℃ | |

|

Hot Melt Adhesive

8832/8832A

|

40D | -40℃~110℃ | 3300 mPa·s/200℃ | |

|

Hot Melt Adhesive

8863/8863A

|

83A | -40℃~120℃ | 3000(mPa·s)/200℃ | |

|

Hot Melt Adhesive

8846/8846A

|

94A | -40℃~130℃ | 5500(mPa·s)/210℃ | |

|

Hot Melt Adhesive

8835/8835A

|

48D | -25℃~150℃ | 4500(mPa·s)/220℃ | |

|

Hot Melt Adhesive

8878/8878A

|

92A | -40℃~140℃ | 4500(mPa·s)/210℃ |

Moisture Content and Storage Guidelines for Low Pressure Molding Materials

Low pressure molding compounds are polyamide-based hot-melt materials with hygroscopic properties. Excessive moisture absorption can cause changes in viscosity, air bubbles, and surface defects during processing. To ensure stable molding performance and consistent product quality, materials should be properly sealed and dried according to their softening points. For more details on moisture control and drying procedures, please refer to the Low Pressure Molding Material Moisture and Drying Guide.