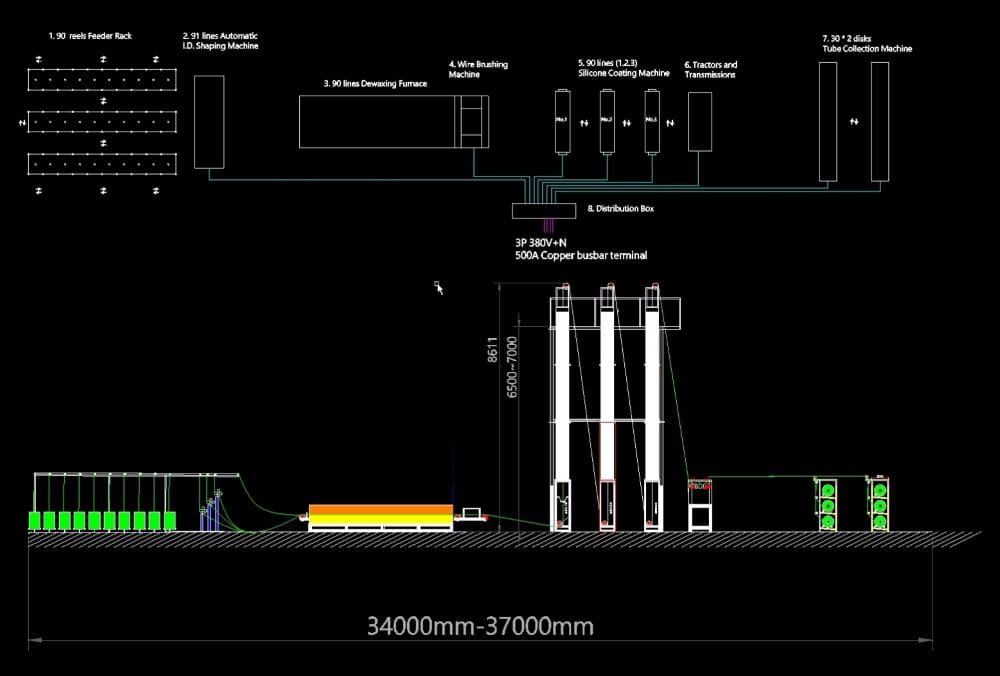

Fiberglass Coated Sleeving Production Line

Introduction

From concept to mass production — a complete turnkey production line backed by 30 years of sleeving manufacturing expertise.

This solution is built around Silicone Fiberglass Sleeving , delivering a fully integrated braiding and coating production process. The package includes customized equipment, optimized process parameters, full line integration, on-site installation, and hands-on operator training.

Expert Consultation & Feasibility Assessment

-

Evaluation of local regulations, facility layout, power requirements, production capacity, and raw material compatibility.

-

Comprehensive analysis of technical feasibility, cost structure, and operational risks.

Choose Goodgi │ Fast, Turnkey Production Line Solutions

✔︎ Goodgi: Manufacturing Roots, Truly Understanding Production Needs

✔︎ Know-how Delivered Directly

Setting up a production line involves extensive testing and hidden costs. We provide proven parameters, process conditions, and standardized operating procedures (SOPs) to help shorten your implementation time.

✔︎ Complete One-Stop Service

-

Custom equipment design

-

Production line planning and workflow layout

-

Operator training + process transfer

-

Pilot production support

-

Equipment in place → Production ready, all in one go

✔︎ International Track Record

Successfully assisted clients in Indonesia and Turkey, covering layout planning, customized equipment, on-site installation, training, and pilot production.

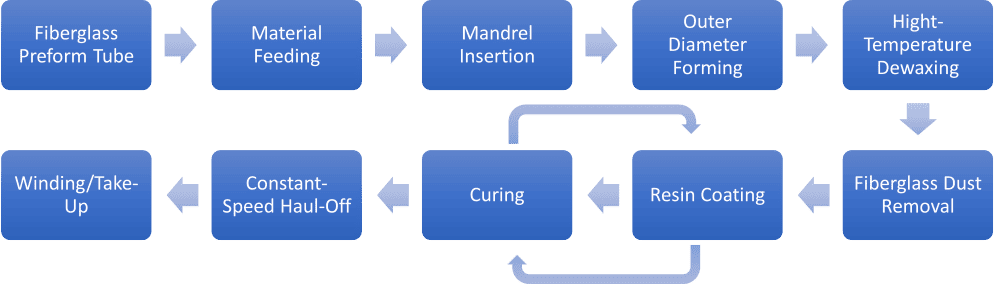

Silicone Fiberglass Sleeving Process

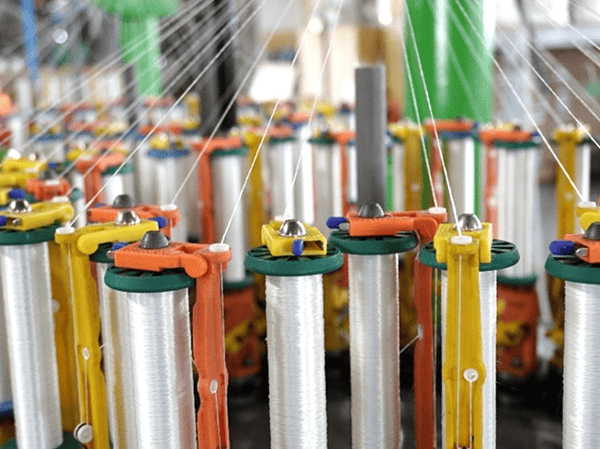

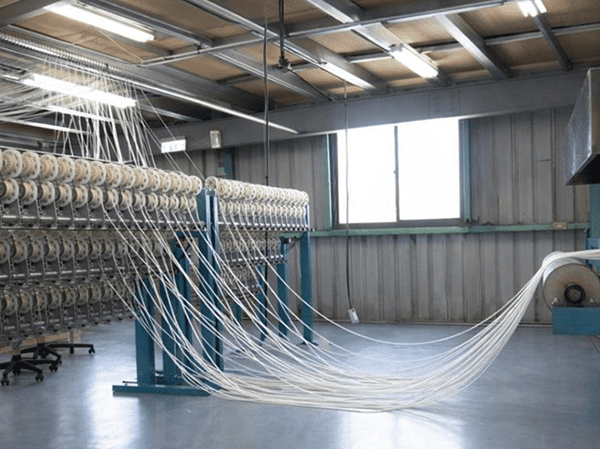

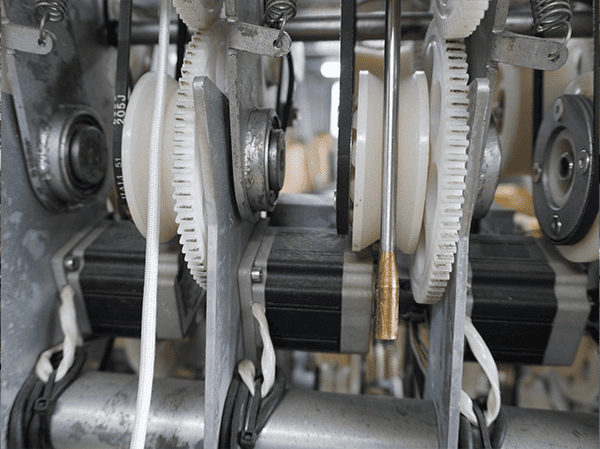

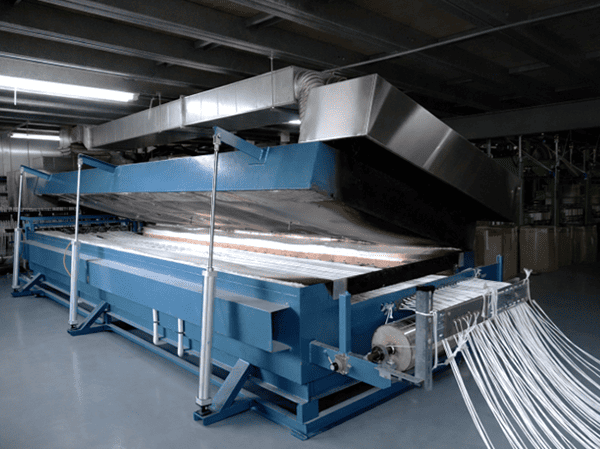

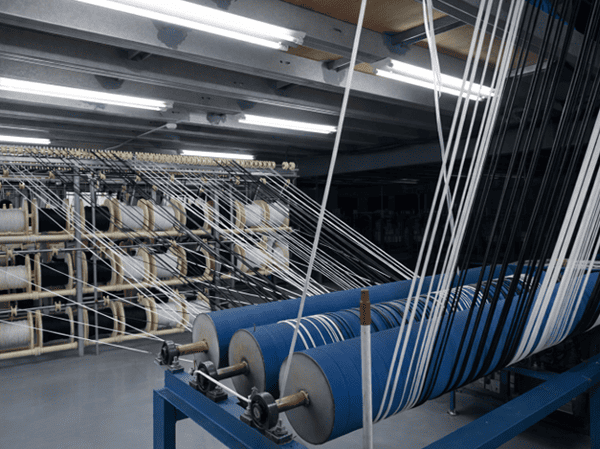

1. Fiberglass Braiding

Braid size, range, speed, number of spools.

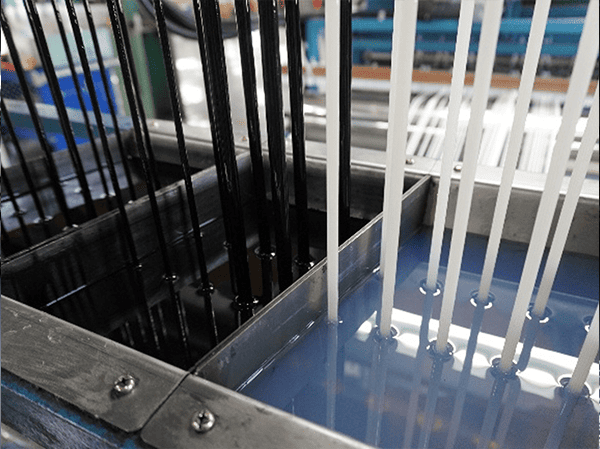

2. Coating

-

Pre-Coating Preparation

-

Coating: Multi-stage temperature-controlled heating system; uniform coating modules with adjustable thickness; curing system; coating method tailored to product specifications.

3. Winding (400m/roll)

Includes repackaging for retail sale.

Coating Process

FAQ

- Q1. Can I implement this without any braiding or coating experience?

- Yes. This solution includes full technical transfer — from equipment setup to process parameters, everything is provided by us.

- Q2. How long does it take from equipment installation to mass production?

- Timeline depends on customization level; typically 4–6 months.

- Q3. What after-sales support is provided?

-

- Online real-time technical support

- Remote formula / parameter diagnostics

- Spare parts supply