Boost High-Speed Cable Reliability: UV Adhesive & Low-Pressure Polyamide for Solder Joints

2025-03-20

|

Table of Contents: |

Background: High-Speed Transmission in Data Centers

In today’s era of high-speed interconnects and data transmission, data centers and AI/GPU servers demand cables with superior reliability. The right adhesive materials not only extend service life but also safeguard signal integrity and mechanical stability throughout manufacturing and operation.

Cable Types: Internal vs. External

External cables (outside the chassis) connect servers, switches, and data center equipment—for example AOC, DAC, ACC/AEC, transceivers, switch power cords, and fiber jumpers.

Internal cables (inside the chassis) link high-speed signals and power within servers, storage, and AI/GPU modules, including MCIO (PCIe Gen5), Oculink/Thinline/GenZ/EDSFF, Multi-Trak, power cables/busbar/liquid-cooling connectors, and harnesses such as SATA, MiniSAS, riser, and leakage sensor cables.

Roles & Applications: Low-Pressure Polyamide Hot-Melt & UV Adhesive

Polyamide Hot-Melt (Low-Pressure Injection)

Used to form-lock and fix cable harnesses away from solder joints. Key benefits include high toughness and abrasion resistance, a low dielectric constant to reduce high-speed loss, strong heat and moisture resistance (e.g., 85 °C/85%RH), and flame retardancy compliant with RoHS/REACH—ideal for robust harness fixation and durability.

UV Adhesive (Solder Joints Protection)

Used to protect solder joints with minimal interference. It cures rapidly under UV light for automated, high-throughput lines, delivers high bond strength (≈17–19 MPa), features very low dielectric constant/loss for stable impedance matching, and shows low water absorption and good formability for high-temperature/high-humidity operation—common in fiber fixation and solder-joint protection.

Adhesive Strategies for Internal/External Cables

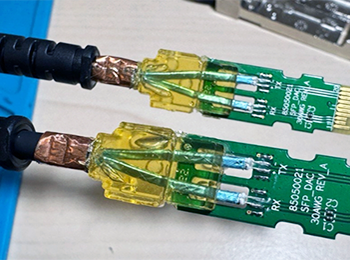

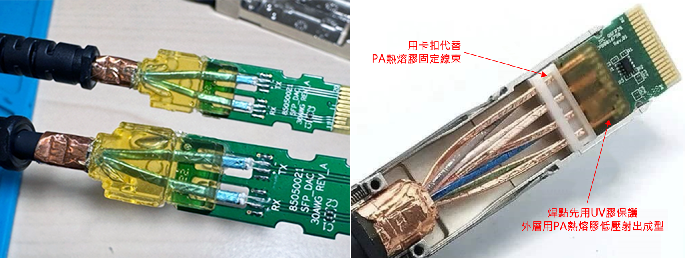

External Cables

Use PA (polyamide) hot melt to secure harness structures and UV adhesive to stabilize fiber/copper terminations; add a metal housing when additional physical protection is required. Single-material options are also viable: PA-only for harness overmolding and external protection, or UV-only for precise solder-joint encapsulation.

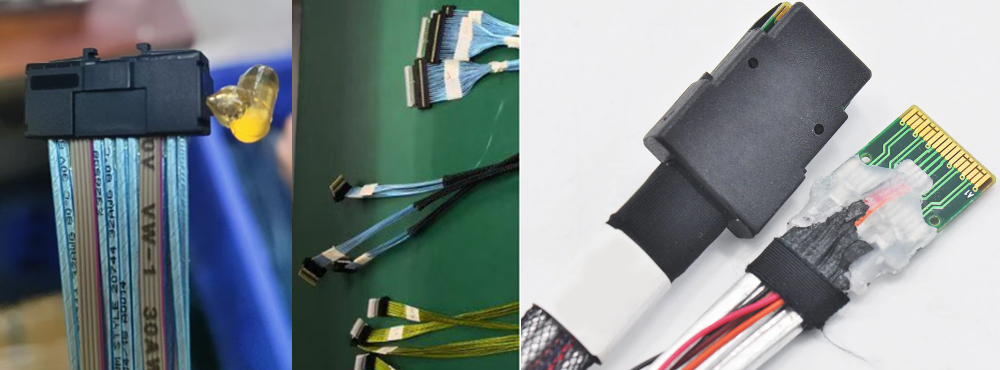

Internal Cables

In tight, vibration-prone spaces, use UV adhesive to seal and protect solder joints while polyamide hot melt forms molded structural protection. Options include UV + traditional housing + PA backfill for sealing and damping, UV + direct-injection PA outer shell for a simplified process, or a three-layer package (UV → PA fill → plastic outer shell) for enhanced stability.

Why Choose UV Adhesive & PA Hot-Melt?

-

Maintain signal integrity: low-k insulation lowers high-speed data loss.

-

Improve mechanical reliability: robust fixation reduces vibration and connector shift

-

Extend service life: moisture/dust/oxidation protection for long duty cycles.

-

Fit automated manufacturing: UV fast-curing and PA low-pressure molding align with smart production lines.

Customer Validation Results

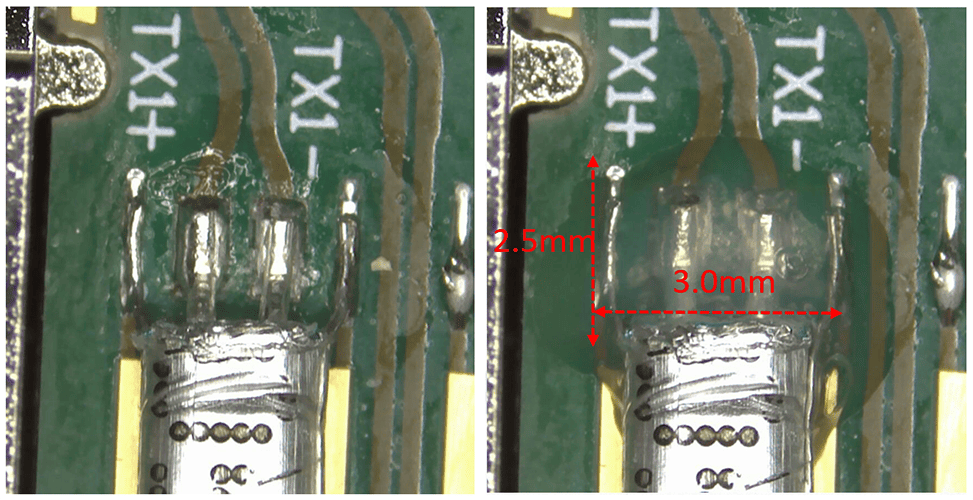

A leading manufacturer in the OSFP ecosystem conducted testing in 2025 to evaluate the application of adhesive 6059 on OSFP modules. As our company focuses solely on adhesive manufacturing and does not possess specialized IR analysis capabilities, the following content is a verbatim summary of the customer’s original test results, presented without any modification or additional interpretation.

Dispensing Appearance & Methodology

Validation was conducted using actual OSFP modules. The adhesive dispensing size was set to 3 × 2.5 × 1.35 mm (height). Insertion Loss (IL) variations were evaluated by comparing measurement results before and after dispensing across multiple frequency points.

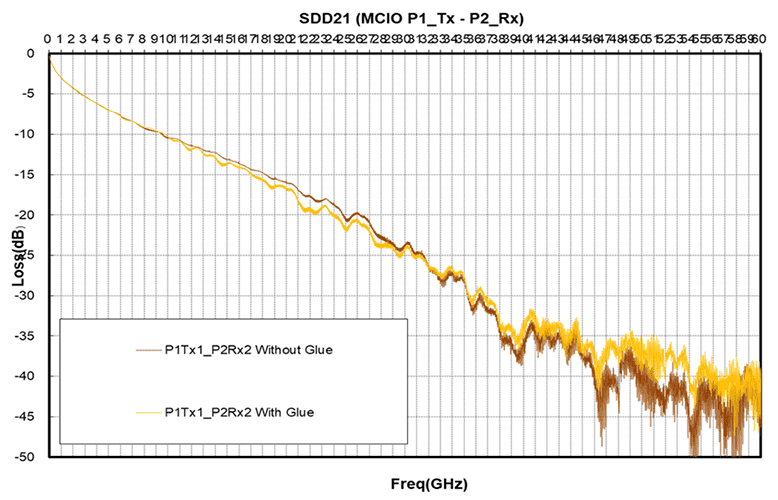

Insertion Loss (IL)

Adhesive was applied to solder-wire areas on both ends of the module. Therefore, post-dispensing data after full application on both sides was compared with pre-dispensing measurements.

-

Primary monitored frequency: 26.56 GHz

-

IL increased by approximately 1.2 dB after dispensing

-

No unacceptable nonlinear behavior observed below 40G

-

Overall results remain within acceptable limits

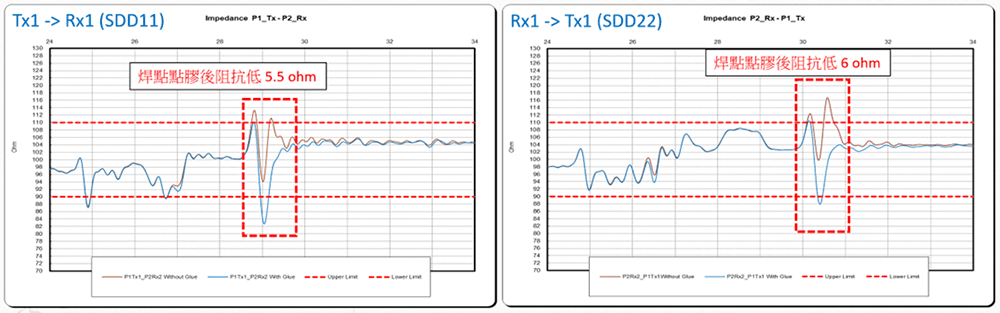

Impedance

Due to the network analyzer’s high measurement frequency and fast rise time, impedance variation under the specified dispensing dimensions remained within the following range:

-

Impedance variation: approximately 5.5–6.0 Ω

-

Within an ideal control range

-

Further optimization is possible by tighter control of dispensing dimensions

Among the evaluated samples, 6059 demonstrated the lowest impact on insertion loss (IL).

FAQ

Q1. Can PA and UV adhesives replace traditional materials?

A. Yes. Their dielectric and mechanical performance is better suited to high-frequency, high-speed applications than conventional hot-melt and silicone materials.

Q2. Do UV adhesives affect transmission quality?

A. Qualified UV adhesives cure to a low and stable dielectric constant and do not interfere with optical or copper-cable signals.

Q3. Will low-pressure molding thermally damage conductors?

A. No. Its molding temperature is lower than conventional injection processes, protecting fine conductors and sensitive components.