Full Protection! Insulation Sleeves for 6 Types of Automotive Wire Harnesses

2023-06-19

The Importance of Wire Harness Protection

As global car sales continue to rise, the market share of electric vehicles is also increasing yearly, undoubtedly playing a crucial role in our lives. Automotive wire harnesses are responsible for connecting various wires in an organized manner to ensure the proper functioning of vehicles. However, automobiles must withstand extreme conditions such as temperature variations, vibrations, and voltage fluctuations. For the considerations of safety and durability in usage, the insulation sleeves that protect these critical wires have become an indispensable assistant. Good Gi, offer a range of heat-resistant, high-voltage-resistant, and durable insulation tubing that provides comprehensive protection for automotive wire harnesses, ensuring that the wires can operate reliably under harsh conditions.

Key Points of Insulation Tubing for Various Automotive Wire Harnesses

| Product | Key features | Product page |

|---|---|---|

| Corrugated Tubing | The wave-shaped design allows for safe bending within a specified range, making it ideal for complex wiring applications. It easily meets the demands of intricate wire routing. | Polypropylene Corrugated Tubing |

| Heat Shrinkable Tubing | With excellent sealing and encapsulation performance, it is highly suitable for use in connections or situations requiring dust, water, and corrosion resistance. It effectively protects the connection area and provides outstanding protective effects. | Polyolefin Heat Shrink Tubing Polyolefin Heat Shrinkable Tubing with Adhesive |

| Fiberglass Sleeving | With outstanding high-temperature resistance, it is widely used in equipment operating in high-temperature environments such as motors and engines. It can withstand extremely high temperatures while safeguarding internal components from heat damage. | High-Temperature Fiberglass Sleeving Fiberglass Silicone Sleeving |

| Extruded PVC Tubing | A cost-effective choice that meets most protection requirements and is easy to use. | Extruded PVC Tubing |

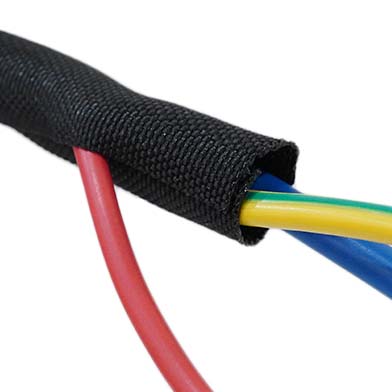

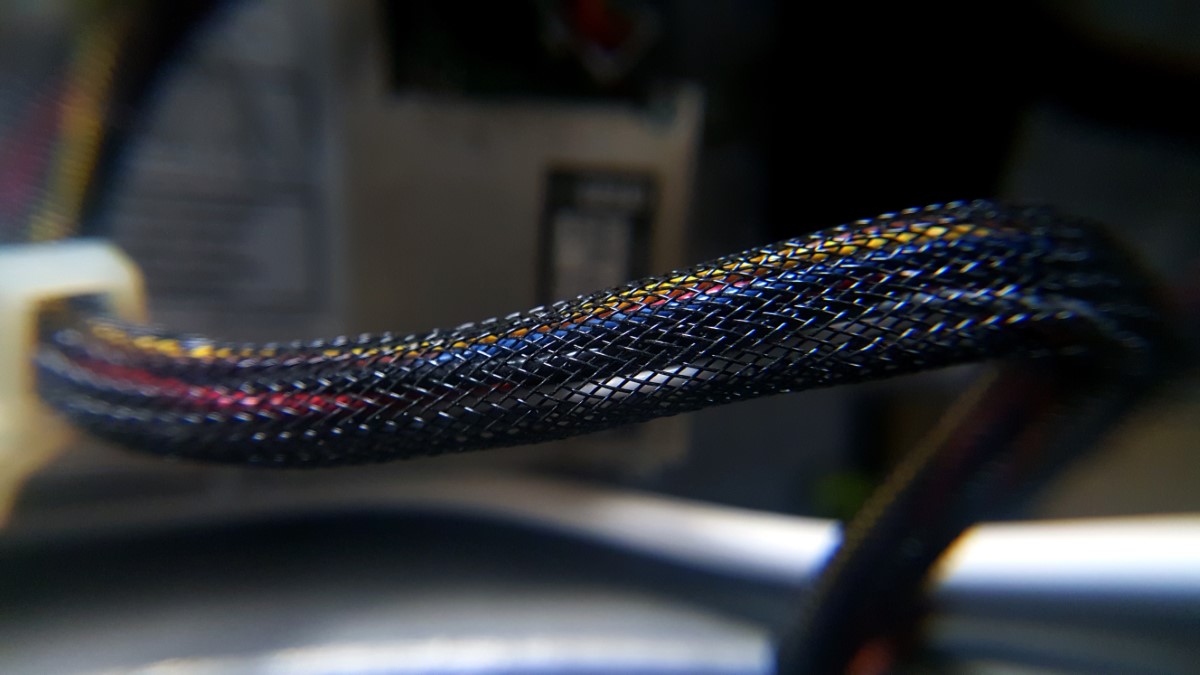

| Expandable Braided Sleeving | The sleeve with excellent breathability and heat dissipation. It is primarily used for cable management, without being restricted by shape and thickness for installation. It remains flexible and adaptable even when covering objects with varying outer diameters. Additionally, the expanded braided tube offers a wide range of color variations, providing a broader selection. | PET Expandable Braided Sleeving |

| Self-wrapping Woven Sleeving | With easy expansion and reusability characteristics, it is highly convenient for installation and subsequent maintenance checks. It can easily expand and retract, making the use of the sleeve more convenient and flexible. | Self-wrapping Woven Sleeving |

Corrugated Tubing: Superior Flexibility and Protection

Made from various plastic materials, including Polyethylene, Polyamide or Nylon, and Polypropylene. (Further reading: What is convoluted tubing?) Among other plastic materials, Polypropylene convoluted tubing is commonly selected for engine surroundings due to its high melting point, excellent flame resistance, and low thermal conductivity. With the high temperatures around the engine, Polypropylene convoluted tubing ensures the protection of surrounding components, prevents fire hazards, and complies with FMVSS 302. Additionally, Polypropylene convoluted tubing has a higher hardness, protecting wires against vibrations and abrasion during vehicle operation.

Heat Shrink Tubing: Effective Enclosure and Protection

Heat shrink tubing has a unique characteristic where its diameter shrinks when subjected to heat, allowing it to encapsulate wires or cable bundles regardless of their shape tightly. It provides insulation, flame resistance, and weather resistance for enhanced protection. Compliant with UL 224, YDPU2, and CUL YDPU8 certification due to the requirement for heat application during installation, it is typically not widely used for large-scale applications. Typical applications include wire terminations or end caps for other tubing. For sealing purposes, adhesive-lined heat shrink tubing can be chosen, as it effectively seals out external factors such as moisture or dust. It has wide applications in waterproofing, leak prevention, and corrosion protection for repairs.

Fiberglass Sleeving: High-Temperature Resistance and Protection

Fiberglass sleeving is a representative material among high-temperature insulation tubing, capable of withstanding temperatures up to 500 ℃. Conforms to flame test UZIQ2 and UZFT2 insulation test in UL 1441. It possesses flame retardant and self-extinguishing properties, making it highly suitable for applications in high-temperature environments, particularly within automotive interiors. It effectively protects against hazards and reduces the risk of incidents. Additionally, fiberglass sleeving offers flexibility, allowing for easier installation. Apart from the automotive sector, it finds widespread applications in aerospace, electronics, industrial machinery, and other industries. It plays a crucial role in these fields. (Further reading: Practical Guide to Fiberglass Sleeving)

Self-wrapping Woven Sleeving: Flexible Installation and Maintenance

Made of polyester monofilaments and multifilaments, self-wrapping woven sleeving possesses characteristics such as flame resistance(Compliant with UZIQ2), abrasion resistance( Compliant with ISO 6722-1:2011), flexibility, and dust protection. Its self-wrapping design allows for both protection and cable management, offering easy and fast installation, as well as convenient modification, maintenance, and inspection of wire harnesses. Widely applications in communication, high-speed rail, automotive, automation equipment, and instrument circuits, especially suitable for use with irregularly shaped wire bundles. (Further reading: Learn more about the characteristics and sizes of self-wrapping woven sleeving)

Extruded PVC Tubing: Cost-effective Comprehensive Protection

Extruded PVC tubing offers characteristics such as voltage resistance, weather resistance, high and low-temperature resistance, flexibility, and resistance to gasoline. Its excellent insulation properties can be widely used in automotive wire harnesses, motors, and wire connections, providing insulation and protection. GoodGi's extruded PVC tubing complies with UL and CSA standards, as well as RoHS and REACH environmental standards, and meets automotive fire protection regulations FMVSS302. This ensures the quality and safety of the product, making it a widely chosen insulation tubing in the automotive industry. (Further reading: Chemical Compatibility Chart for PVC Tubing)

PET Expandable Braided Sleeving: Excellent Breathability and Heat Dissipation

PET Expandable Braided Sleeving is highly flexible and can expand to approximately twice its diameter, making it suitable for irregularly shaped wire harnesses. In addition to providing protection, it also facilitates wire organization. Made from PET material, it offers flame resistance(Compliant with UZIQ2), chemical corrosion resistance, excellent heat dissipation, and breathability. It possesses remarkable characteristics such as flexibility, impact resistance, and abrasion resistance( Compliant with ISO 6722-1:2011).

We hope this article has provided you with valuable information. Whether it's Fiberglass Sleeving, Heat Shrink Tubing, Self-wrapping Woven Sleeving, Extruded PVC Tubing, or PET Expandable Braided Sleeving, each type of sleeving has its unique advantages and characteristics to meet different needs. If you have any questions about insulation sleeves or need professional advice, quotations, or alternative options, we are always ready to assist you. Our team has extensive experience and expertise and is dedicated to providing support and answers. Contact us now and let us ensure comprehensive protection for your wire harness under various conditions.