Where to buy Corrugated Tubing? What is the applications of Corrugated Tubing for? What kinds of spec. can meet your needs?

2022-04-22|

Table of contents |

As a user or buyer, when browsing the website, you will find a lot of suppliers and agents of corrugated tubes. But, how to choose a qualified and suitable spec.?

The following steps will help you to find suitable tubes.

-

Ensure the quality and specifications meet your needs.

-

Check the product specification through the supplier's website.

-

Are there any international certifications, such as UL, CSA, or third-party testing reports (RoHS, REACH, etc.) to ensure that the products are environmentally friendly?

-

Quality testing equipment, production traceability records, and quality control procedures are also key points to check if this supplier is qualified.

Good Gi Co., Ltd is a professional company of manufacturing tubes and selling products to many countries. We believe that we can meet the needs of customers and provide suitable products, and customized services for customers.

Applications Of Corrugated Tubing

Different materials bring different applications. Plastic and Metal are the main materials for Corrugated tubes. More information below:

-

Polypropylene Corrugated Tubing

Good elasticity, good ductility, good flexibility, flame retardant, and insulation, widely used in automobile, and outdoor wiring harnesses, protecting wires and cables from external damages. When the number of wiring harnesses is large and messy, using a corrugated tube will be a good way of wire management.

If using it in the interior of vehicles, FMVSS302 certification is necessary to ensure the Polypropylene corrugated Tubing is flame retardant.

Besides RoHS, REACH, FMVSS302, and other certifications, Japanese vehicle manufacturers also require Polypropylene corrugated tubes with heat resistance, oil resistance, cold resistance qualified elongation rate, deformation rate, etc.

-

Polyamide Corrugated Tubing - Material: Nylon 6

Good elasticity, higher hardness than polypropylene Corrugated Tubing, glossy surface, impact resistance, not easy to deform and break, wear resistance, fire and flame retardant, oil resistance, acid and alkali resistance, good recovery, and other characteristics.

Widely used in automotive wiring harnesses, power equipment, automation equipment, motors, and other fields to protect wires from external damages.

If used in high-end automation equipment, the tube will be required to comply with UL1696 UL Standard for Safety Mechanical Protection Tubing (MPT) certification.

Read-Around: UL-certified nylon tube is used in automatic control equipment factory

-

HDPE Corrugated Tubing - Material: Polyvinylchloride

Due to its low cost, it is widely used in construction, decoration, and other cable protection. Compared with PP and PA materials, it is softer with good bending. And It is less space-restricted and light in weight. Also, it is used in wiring on the ceiling.

However, if comparing the long-term temperature resistance, the performance of Polypropylene and polyamide is better than HDPE corrugated Tubing. And HDPE corrugated Tubing is not flame retardant. Therefore, it’s not suitable for use in automotive, industrial, and electronic products.

-

Galvanized Metal Corrugated Tubing - Material: Galvanized Steel

It is soft and resistant to bending, the interior is smooth and it is easier to pass the wire, and it is resistant to high temperature, corrosion, and pressure. It is used for wire and cable protection in indoor and outdoor environments such as automobile industry, automation equipment, machinery, engineering equipment, aviation railway track equipment, ships, chemical industry, communication systems, etc.

.jpg)

If waterproofing is required, there is another waterproof metal Corrugated Tubing can be chosen. The difference is that the exterior of the waterproof type is covered with a layer of PVC so that liquid and gas will not penetrate.

How to choose the specifications of the corrugated tube?

-

First of all, the material depends on the environmental situation.

-

If considering the pressure resistance, you can use Polyamide nylon Corrugated Tubing.

-

If you need EMI shielding, you can consider metal Corrugated Tubing.

-

If concerning the cost, you can choose Polypropylene Corrugated Tubing.

-

-

Select The Suitable Corrugated Tubing Size

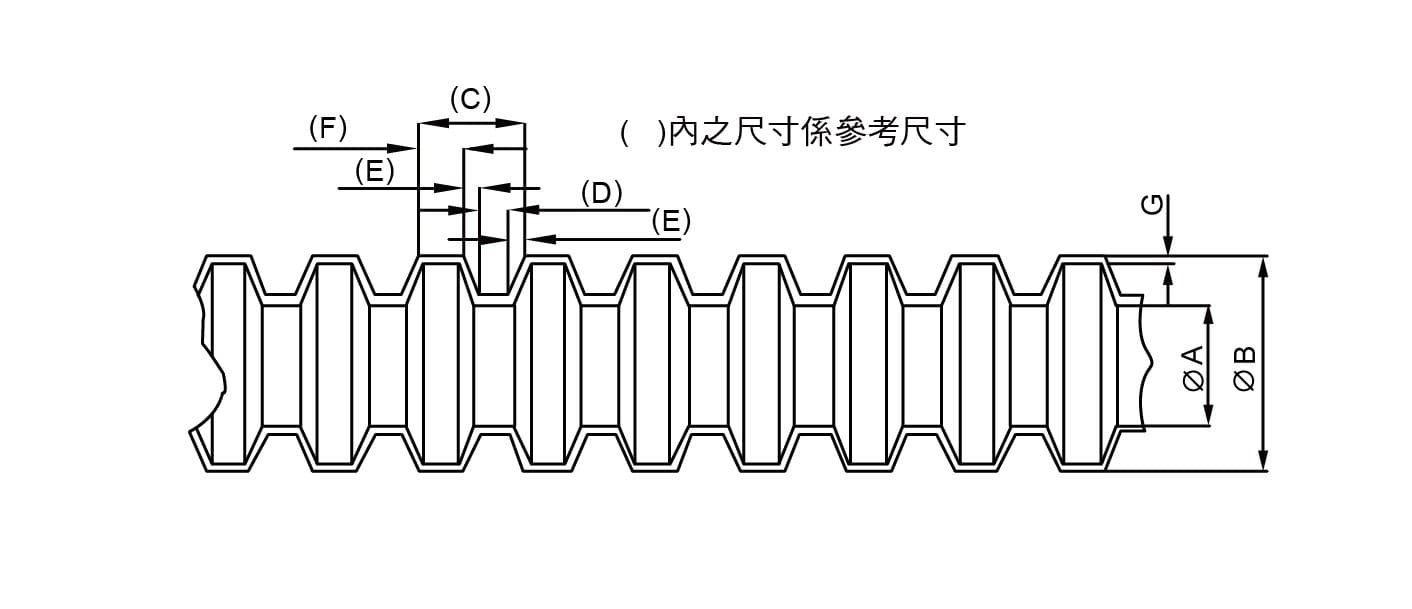

In the above picture, ΦA is the inner diameter of the corrugated tube, which corresponds to the outer diameter of the cable to be sheathed. So, a corrugated tube with an inner diameter of Φ5 can be selected for a wire harness with an outer diameter of Φ3.

ΦB in the above figure refers to the outer diameter of the corrugated tube, which is used to confirm whether it will interfere with the mechanism. If it is to be assembled with the corrugated tube fitting, it is necessary to notice whether the outer diameter meets the specifications.

In addition, most of the car wire harnesses are very long and difficult to pass through, or the connectors or terminals have been assembled, and the outer diameter of the connector is too large to pass through the corrugated tube. To solve this problem, you can choose a split corrugated tube and the wire harness can be directly inserted into the corrugated tube.

We, Good Gi Co., Ltd, are very pleased to provide you with samples if you’re willing to use our tubes on your products. Please contact us if you have any concerns.