What are the uses of Cable Glands?

2022-09-21|

Table of Contents: |

-

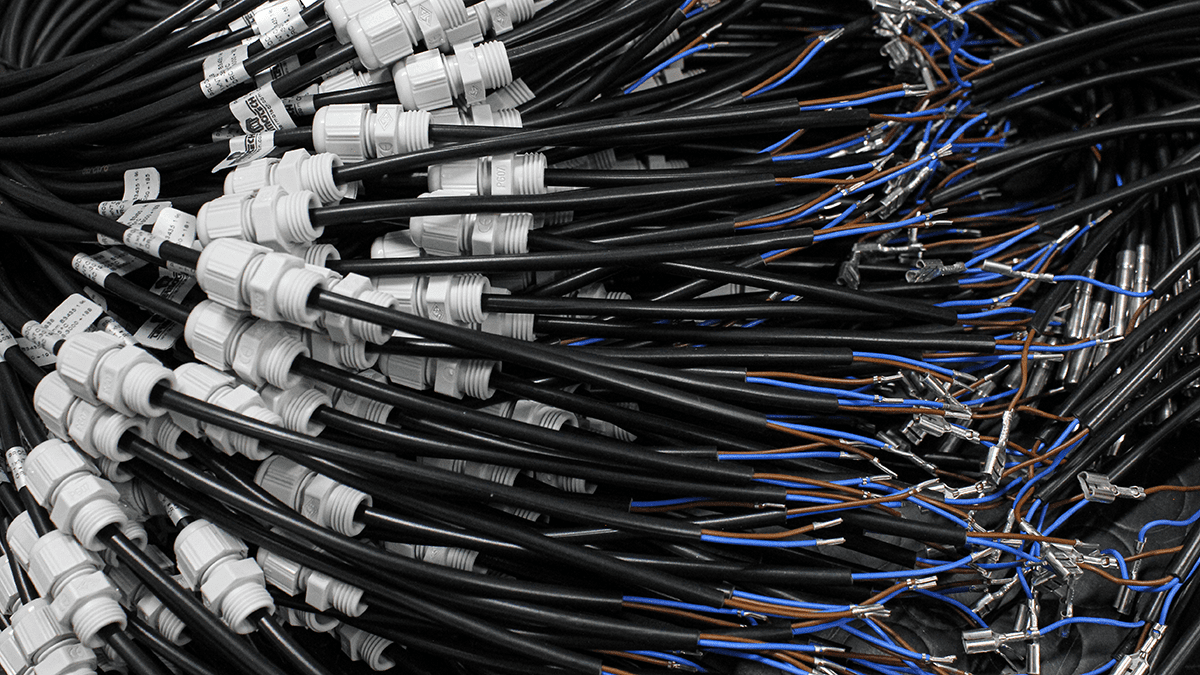

What is a cable gland used for?

As a part of the equipment, the cable gland is not only a connection between the tube and equipment but also plays an important role in insulation protection. Installed at the end of the cable, allowing the tubes to safely pass through the housing to connect the mechanical equipment and prevent the problems of twisting and pulling. Keep the sealing of the cable outlet hole and the connection end of the mechanical equipment, avoid the intrusion of moisture and dust, which cause poor insulation, shorten the life of electronic products, and cause the danger of short circuit explosion.

Application of Cable gland

-

Industrial Cable Gland– To cope with high temperatures or harsh environments while meeting a high degree of safety, it is necessary to meet the necessary additional functions when selecting.

-

Marine Cable Gland – Installing the cable glands in instruments such as satellite navigation, GPS, and radar on the ship, provides excellent air tightness according to the marine environment and has the characteristics of high waterproof and salt resistance.

-

-

How many types of cable glands are there?

-

Material of Cable Gland

-

Nylon Cable Gland

It is commonly used in conjunction with cables in general environments and can clamp tubes and has high installation efficiency with IP68 dustproof and waterproof, 94V-2 fireproof grade, oil resistance, alcohol resistance, and widespread solvent resistance.

-

Zinc Alloy Cable Gland

Used in conjunction with metal hoses, the structure is tight and high in strength. It can be dustproof and waterproof, resistant to alcohol, oil, and general solvents, and is preferably used for high mechanical strength equipment and outdoor use.

-

Brass Cable Gland

Brass with nickel plated is resistant to salt water, chemicals, and corrosion. Stainless Steel Cable Gland: with higher corrosion resistance; for high mechanical strength or harsh environments.

-

Stainless Steel Cable Gland

High corrosion resistance, used in high-strength mechanical requirements or harsh environments

-

Special material Cable Gland

used in an environment with special requirements, such as oil resistance, cold resistance, flame retardant, high-temperature resistance, etc.

-

-

Thread Specifications of Cable Gland

-

PG, Panzergewind

-

M, Metric thread ISO Metric

-

G / PF / BSP / PS

-

NPT

-

-

The function of Cable Gland

Dust-proof / water-proof / oil resistant / solvent resistant/explosion-proof/tensile / acid resistant / salt resistant/fire-proof / flame retardant

-

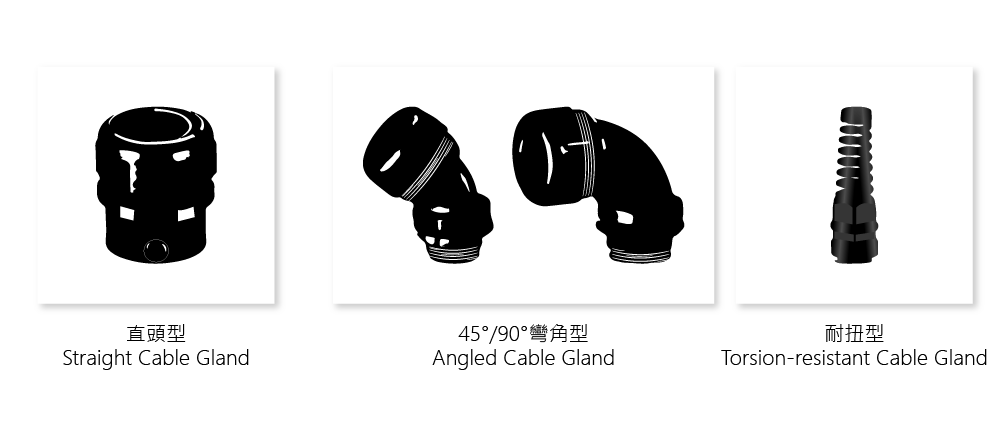

Type of Cable Gland

-

-

How to choose a cable gland?

★ Contact Good GI to get samples and solutions faster ★

-

According to the external environment and application to choose『Material』.

-

Installation Method - Choosing a suitable cable gland type

-

Operating Temp - Lowest temp. and Highest temp.

-

Flame Retardant- UL 94 is a plastics flammability standard released by the Underwriters Laboratories(USA).

94V-0

Burning stops within 10 seconds on a vertical part, allowing for no inflamed plastic drops.

94V-1

Burning stops within 30 seconds on a vertical part, allowing for no inflamed plastic drops.

94V-2

Burning stops within 30 seconds on a part allowing for drops of vertical flammable plastic.

-

Pressure Rating - The maximum pressure the cable can withstand before leaking or breaking

-

IP Rating- IP each digit indicates the protection level

IP_X First digit: Solid particle protection - Single numeral: 0~6

IPX_ Second digit: Liquid ingress protection - Single numeral: 0~8Common IP Rating and Application:

-

IP66 – For outdoor use and can withstand wind and rain to prevent moisture from entering.

-

IP67 – The anti-intrusion type is most commonly used, providing waterproof protection up to 1 meter underwater for 30 minutes of immersion.

-

IP68 -The underwater type is designed for use in demanding installations, providing waterproof protection for 30 minutes of immersion within 1.5 meters of water.

-

-

-

According to「 Outlet direction of device」to choose a suitable 『Type』for use.

-

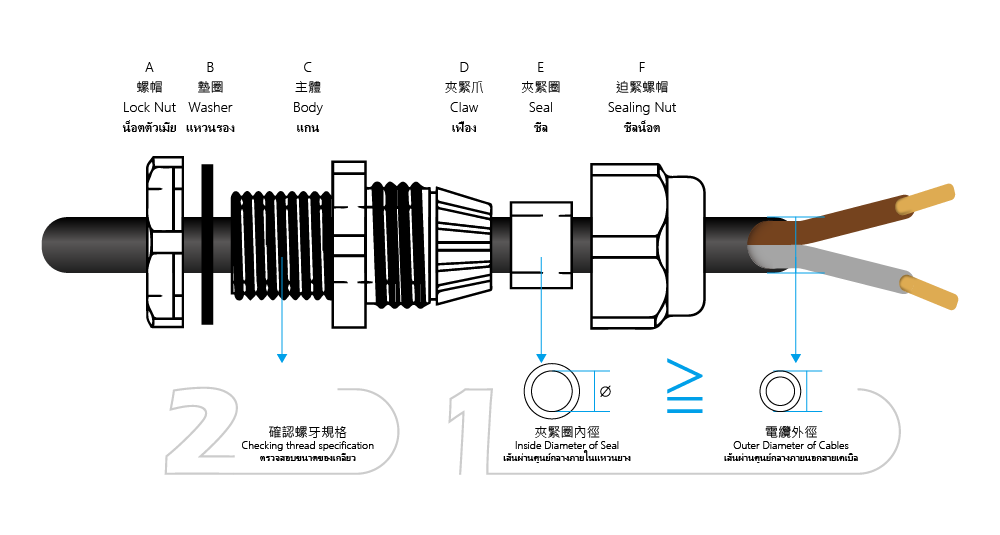

The inner diameter of cable gland clamping ring ≧ Otter diameter of Cable. Also checking thread specifications. (Please refer to the picture below)

-