Low-Pressure Molding Technology: Cost-Effective, Eco-Friendly, and Faster

2023-09-06

|

Table of contents: |

Packaging technology plays a critical role in protecting electronic components and products in the manufacturing industry. "Low-pressure molding" is an innovative packaging method gaining widespread attention and usage, particularly as a viable replacement for traditional potting techniques. This article delves into the concept, advantages, and application areas of low-pressure molding.

What is Low-Pressure Molding?

Low-pressure molding(LPM), also known as "low-pressure over-molding" or "low-pressure injection molding," is, as the name suggests, a low-pressure encapsulation and protective manufacturing process primarily employed for sensitive electronic components, such as circuit boards. This innovative technique utilizes low-pressure injection of hot melt adhesive, which is a thermoplastic material. The hot melt adhesive operates at lower temperatures and pressures compared to traditional molding processes, making it an excellent packaging solution for fragile and sensitive electronic components. This gentle encapsulation process ensures the protection of delicate parts while also offering benefits such as reduced cycle times and increased production efficiency in the manufacturing of electronic devices.

Advantages of Low-Pressure Molding

Time Saved + Labor Reduced + Material Saved = Cost Reduction

-

Time Saved: Compared to traditional potting, heating, and curing times are significantly reduced, leading to shorter production cycles. Additionally, the use of multi-cavity molds can enhance output rates.

-

Labor Reduced: The low-pressure molding process is straightforward, requiring only the placement of components into molds and the activation of the injection button. This reduces the technical skill required of operators, significantly lowering the risk of operational errors and ensuring high yields and stability.

-

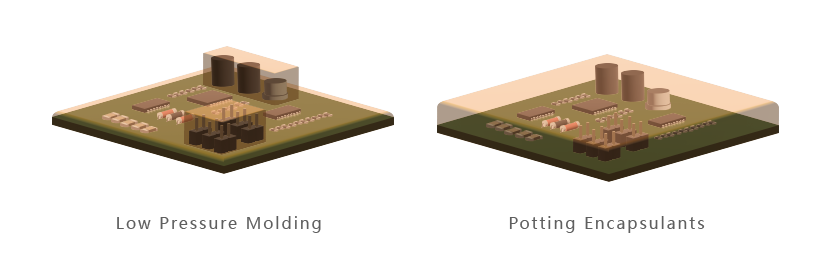

Material Saved: As depicted in Figure 1, low-pressure injection allows for freedom in shaping without the constraints of enclosure space, enabling the material to be applied where needed, resulting in a substantial reduction in material usage.

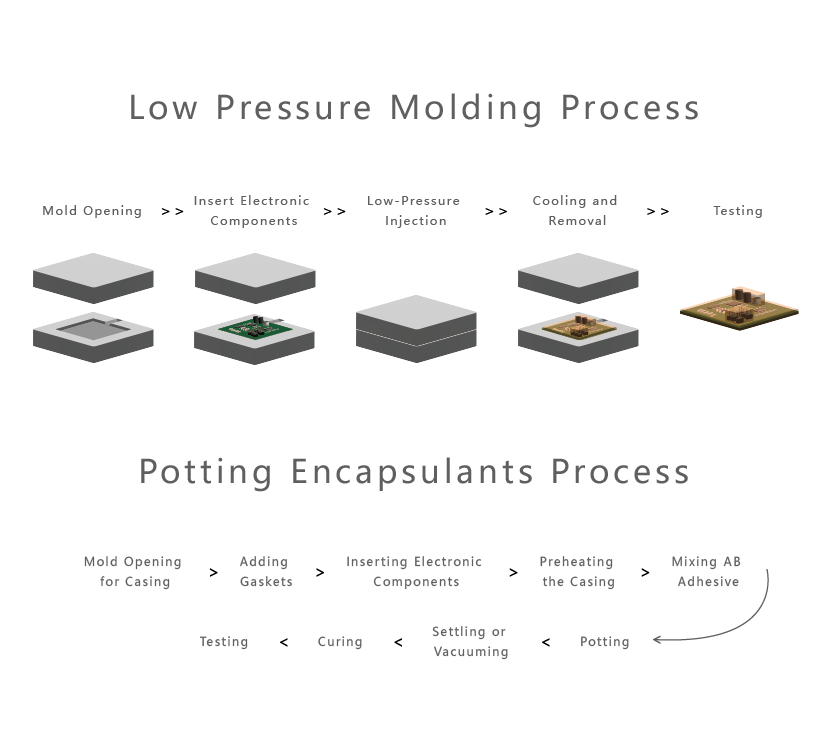

Low-Pressure Molding Process

Low-pressure molding involves using molds to secure and encapsulate electronic components. Both the low-pressure injection mold and the low-pressure injection equipment are crucial components of the Low-pressure molding process, determining production efficiency and yield.

Low-pressure molding can be succinctly divided into 3 steps:

-

Placing electronic components into the mold.

-

Injecting low-pressure material to completely encase the electronic components.

-

Opening the mold indicates that the material has cooled and can be removed.

Effective mold design can minimize defects such as bubbles, voids, shrinkage, or flash.

Low-Pressure Molding Materials

Low-pressure molding materials are specialized hot-melt polyamide compounds engineered for electronic encapsulation, cable assembly, and connector protection. These thermoplastic resins are based on polyamide (PA) chemistry, synthesized through polymerization reactions and precisely compounded with performance additives to achieve targeted viscosity, adhesion strength, and mechanical properties.

The material is melt-processed and injected under low pressure, providing gentle encapsulation without damaging sensitive components. Upon cooling, it solidifies to form a durable, protective coating that offers mechanical strength, insulation, and environmental resistance. Different formulations vary in melting point, adhesion, hardness, temperature resistance, and flow behavior.

Moisture Sensitivity and Pre-Drying

Low-pressure molding compounds are co-polyamide-based thermoplastics with moderate moisture absorption characteristics. Moisture can act as a plasticizer, reducing tensile strength, modulus, and viscosity. Excessive moisture often leads to bubbles, voids, and surface defects during molding.

To ensure processing stability and surface quality, the moisture content must remain below the manufacturer’s specification, and drying is required if materials are exposed to humidity.

Storage & Drying Guidelines

-

Store sealed bags in a cool, dry, and shaded area.

-

Reseal opened bags immediately to prevent moisture absorption.

-

If moisture contamination occurs, pre-dry the pellets before use.

Recommended Drying Conditions:

-

Softening point below 170°C: Vacuum dry at 70°C for ≥3 hours

-

Softening point above 180°C: Vacuum dry at 80°C for ≥4 hours

-

Without vacuum:

-

High-softening-point grades → 100°C hot-air drying for 4+ hours

-

Low-softening-point grades → 70°C extended drying, preferably with forced air circulation

-

Because formulation directly impacts melting behavior, hardness, heat stability, and flow rate, proper storage, moisture control, and pre-drying are essential to ensure consistent encapsulation quality and molding performance.

How to Choose Low-Pressure Injection Materials?

-

Environmental Requirements: Consider factors like temperature, humidity, exposure to chemical environments, UV exposure, and more.

-

Mechanical Strength Requirements: Evaluate hardness, flexibility, stress tolerance, flexibility, and impact resistance, among other factors.

-

Sealing Requirements: Determine the required waterproofing level or airtightness, such as IPX8 or positive pressure 50kPa.

The selection of the most suitable material depends on a comprehensive assessment of specific application requirements and the pros and cons of the materials involved.