Polyamide(Nylon) Convoluted Tubing

GPA-X

Overview

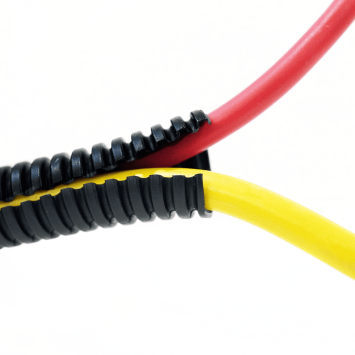

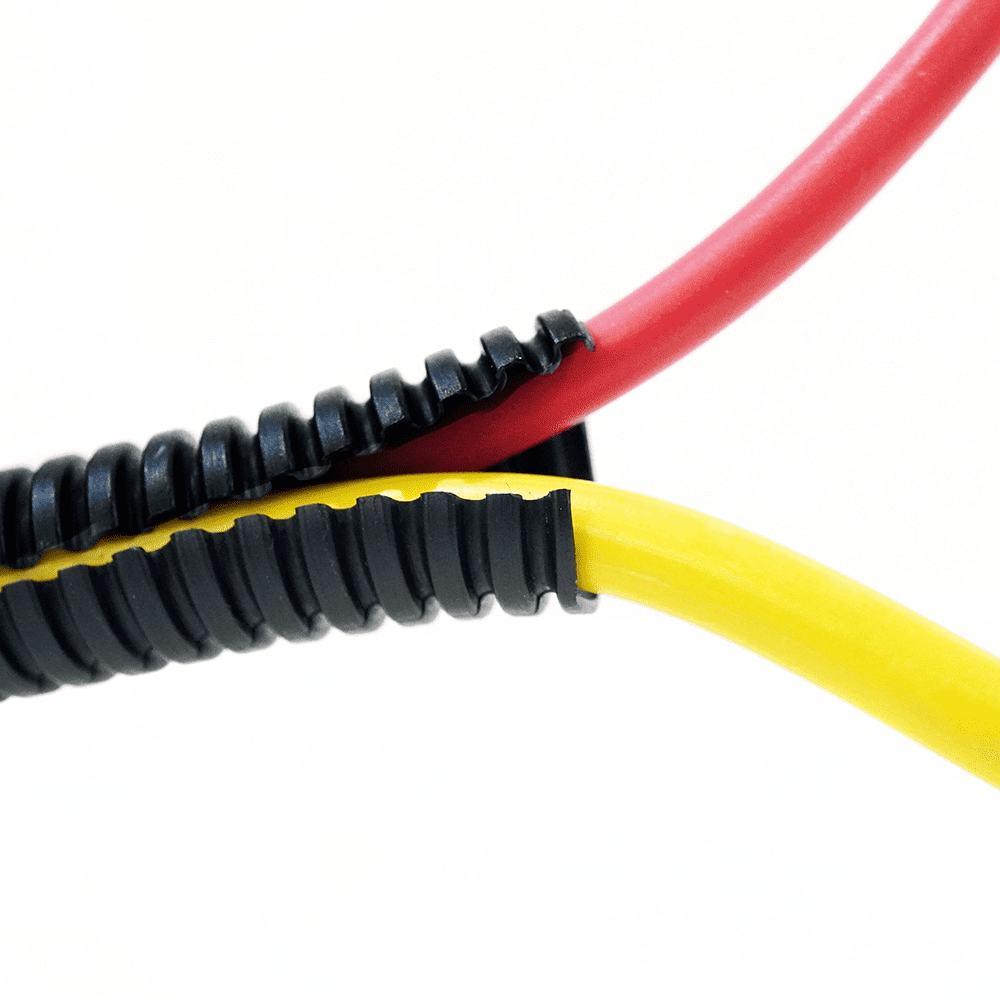

Polypropylene convoluted tubing

is renowned for its superior elasticity, plasticity, and glossy surface, providing excellent resistance to impact, deformation, and cracking. It also offers durability against abrasion, oil, acids, and alkalis, making it ideal for protecting wiring from damage. Commonly used in the automotive industry for wiring harnesses, as well as in power equipment, automation systems, and motors, this tubing meets the UL1696 and RoHS standards. Furthermore, it serves as a reliable alternative to PA nylon tubing from brands such as Panduit®, HellermannTyton®, and GREMCO®, offering comparable performance and protection for various demanding applications.

Features

- Material: Nylon 6/ Polyamide Nylon6

- Working temperature: -10℃~120℃

- Color: Black, Customized colors are also welcome.

- Flame retardant grade: VW-1

- UL NO. E501693

Video

Q&A

-

Uses of nylon corrugated tube

Nylon corrugated tube is a versatile cable management and protection solution commonly used in various industries. It is particularly useful in applications where wires and cables need protection from harsh environments or when routing around tight corners is necessary.

The automotive industry frequently uses nylon corrugated tube to protect wiring from damage caused by vibration, moisture, and temperature fluctuations. The electronic and electrical industries also benefit from its use for cable management and protection of sensitive components from abrasion, impact, and chemicals.

Other industries such as medical equipment, aerospace, and telecommunications find nylon corrugated tube appealing due to its ability to withstand high temperatures and its good insulation properties. It is also a popular choice for DIY and household projects.

Overall, nylon corrugated tube is a reliable and durable solution for protecting and managing cables and wires. Its high flexibility, resistance to abrasion and chemicals, good insulation properties, and ability to withstand high temperatures make it a suitable option for various industries. -

Features of Nylon Corrugated

Nylon corrugated tube exhibits several key characteristics that make it a popular choice for protecting and managing cables and wires in various industries. Its good elasticity allows it to bend and stretch without breaking or cracking, making it highly flexible for a wide range of applications.

The tube's shiny surface not only enhances its appearance but also helps it resist dirt and dust. Its impact resistance protects cables and wires from damage caused by external forces, while its resistance to deformation and cracking helps to maintain its shape even under extreme temperatures or pressure.

Additionally, nylon corrugated tube's abrasion resistance shields cables and wires from damage caused by friction, while its oil resistance makes it ideal for use in the automotive industry. The tube's acid and alkali resistance also allows it to perform well in harsh environments. Overall, these characteristics make nylon corrugated tube a reliable and versatile solution for cable management and protection in various industries.

-

Tips for Selecting the Right Size of Nylon Corrugated Conduits

Choosing the correct size of nylon corrugated conduit is crucial to ensure the proper protection of wires and cables. The size of the conduit should be selected based on the diameter of the wires or cables that will be passing through it.

To choose the right size, measure the outer diameter of the largest cable or wire that will be routed through the conduit. Then, select a conduit size that is at least 25% larger than the diameter of the cable or wire. This will ensure that there is enough space for the cables to move freely within the conduit without causing excessive friction or damage.

It is important to note that selecting a conduit that is too small for the cables or wires can lead to overheating and damage due to increased friction and limited air circulation. On the other hand, choosing a conduit that is too large may result in the cables moving around and potentially causing damage to themselves or other components.

Therefore, it is essential to carefully measure the cables or wires and choose a nylon corrugated conduit that is the appropriate size for the application.

Certificate from the Third Party

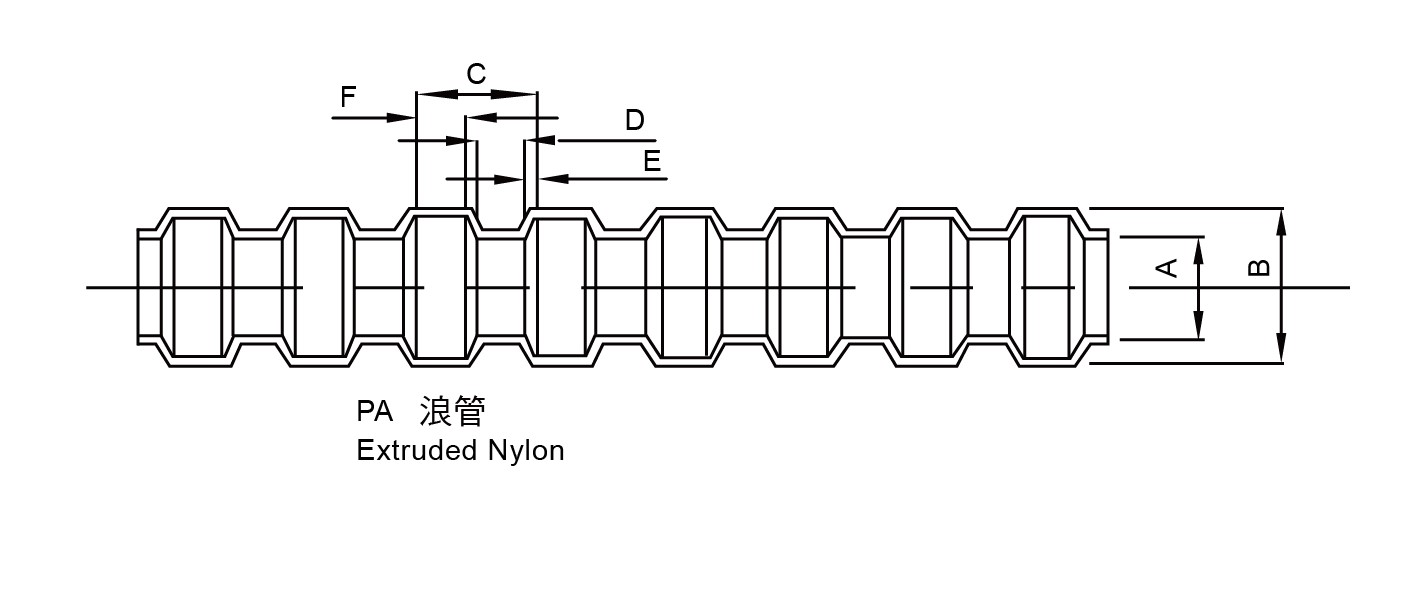

Engineering Picture

Features

| {{ typeOne.merge }} |

|---|

| {{ itemOneTitle }} |

| {{ item }} |

Specifications

| {{ typeTwo.merge }} |

|---|

| {{ itemTwoTitle }} |

| {{ item }} |

| {{ typeThree.merge }} |

|---|

| {{ itemThreeTitle }} |

| {{ item }} |